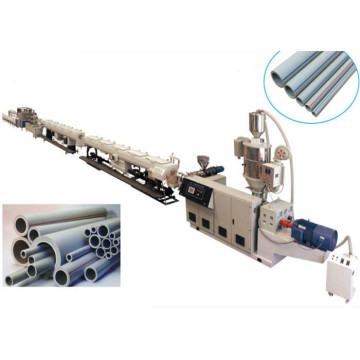

Click on the follow link to find out more information: https://www.langboextrusion.com/pe-pipe-extrusion-line/

Company Info

- Company Name: Zhangjiagang Langbo Machinery Co. Ltd.

- Representative: Bofeng YIN

- Product/Service: Pipe Extrusion Line , Profile Extrusion Line , Plastic Recycling Equipment , Co-Extrusion Line , Plastic Granulating Equipment , Granulating Equipment

- Capital (Million US $): 500000RMB

- Year Established: 2012

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: Above 20

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Lefeng Road 99. Leyu town, Zhangjiagang City, China

- Contact Person: Ms. Emma LIU

- Tel: +86-139-21974941

Premium Related Products

Other Products

Hot Products

High Speed Rotogravure Printing Machine (ASY-600-800-1000)Stretch Cling Film MachinePOF 3-Layer Co-Extrusion Polyolefin Hot Shrink Film ExtruderPE Hot-Shrinkable Film MachinePVC Stretch Cling Film MachineModel Sj500-1700 3-7 Layer Co-Extrusion Film Blowing MachineHydraulic Pressure Rock-Arm Decide Machine (BX-10T)PP Down Blowing 3 Layer Co-Extrusion Film Blowing Machine6 Colors High Speed Flexo Printing Machine (CE)High-Speed (tri-servo) Tri-Sealing Zipper Vertical Bag Making MachineVertical Automatic Slitting MachinePVC Hot Shrink Film Blowing Machine with Rotating TractionAutomatic Multifunction Patch Bag Making MachineGbde Computer Control Double Line Bag Making MachineThree to Five Layers Co-Extrusion Film Blowing MachineMuti Layer Coextruding Agriculture Thick Film Blowing Machine