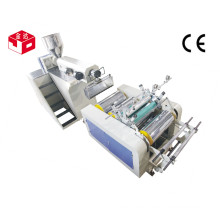

PVC Hot Shrink Film Blowing Machine with Rotating Traction

- Productivity:

- 100/Minth

- Place of Origin:

- Zhejiang China

- Supply Ability:

- 100/Minth

- Certificate:

- CE, ISO9001

Basic Info

Model No.: SJ-50 (55-60)

Product Description

Model NO.: SJ-50 (55-60) Raw Material: PVC Screw Diameter: 50/55/60mm Computerized: Non-Computerized Certification: CE, ISO9001:2008, SGS Film Thickness: 0.02-0.08mm Specification: CE HS Code: 847730900 Type: PVC Film Blowing Machine Maximum Folding Width of Film: 70-600mm Automation: Automatic Machine Weight: 1.5/1.8/2.2 T Screw L/D Ratio: 28:1 Trademark: Jinda Origin: Zhejiang China The PVC Shrinkable Film Blowing Machine adopts the upper tractor for 360 degree continuous rotation it make the film more stable.

The set comprises of a plastic extruder, an air ring, a head, an upper tractor for rotation, a cooling device, a heating device for expanding, a coiling device and a motor controlling system.

The set adopts the upper tractor for 360 degree continuous rotation, which is more stable than the rotation with a normal die head and the film is coiled flatter. Due to the upper tractor, the work of cleaning the screw and the residual impurity in each channel after the machine halts can be left out. As for the normal rotatable die head, it is required for dismantling the complicated rotating part.

Both the screw and the machine barrel are made of superior alloy steel-38CrMoAl. After finish machining, the parts are hardened through nitrogen treatment, so they have the advantages of high hardness, wear resistance and corrosion resistance.

Adopt a new type screw, which length-diameter ratio is 28: 1. The screw is especially adapted for mixing and plasticizing the PVC, which has advantages of high melt viscosity and bad thermal stability. The screw can strengthen the degree of plasticification.

An automatic temperature control system provided with a digital display is used for controlling the heaters and machine body cooling fan in order to enable the temperature during plasticiaztion to be stable and accurate and enable the plasticization to meet the requirements of film production process more so as to ensure the quality of heat shrinkable film.

Both the die head and the air ring are specially treated to make the plasticization and cooling effect better.

The internal surface of die head is mirror polished and plated with hard chrome so as to reduce the film splits and increase the service lift of die head.

The set has the advantages of compact structure, high degrdd of automation, centralized control and easy operation.

Contact us if you need more details on PVC Film Machine. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about PVC Hot Shrink Film、PVC Heat Shrink Film. If these products fail to match your need, please contact us and we would like to provide relevant information.

The set comprises of a plastic extruder, an air ring, a head, an upper tractor for rotation, a cooling device, a heating device for expanding, a coiling device and a motor controlling system.

The set adopts the upper tractor for 360 degree continuous rotation, which is more stable than the rotation with a normal die head and the film is coiled flatter. Due to the upper tractor, the work of cleaning the screw and the residual impurity in each channel after the machine halts can be left out. As for the normal rotatable die head, it is required for dismantling the complicated rotating part.

Both the screw and the machine barrel are made of superior alloy steel-38CrMoAl. After finish machining, the parts are hardened through nitrogen treatment, so they have the advantages of high hardness, wear resistance and corrosion resistance.

Adopt a new type screw, which length-diameter ratio is 28: 1. The screw is especially adapted for mixing and plasticizing the PVC, which has advantages of high melt viscosity and bad thermal stability. The screw can strengthen the degree of plasticification.

An automatic temperature control system provided with a digital display is used for controlling the heaters and machine body cooling fan in order to enable the temperature during plasticiaztion to be stable and accurate and enable the plasticization to meet the requirements of film production process more so as to ensure the quality of heat shrinkable film.

Both the die head and the air ring are specially treated to make the plasticization and cooling effect better.

The internal surface of die head is mirror polished and plated with hard chrome so as to reduce the film splits and increase the service lift of die head.

The set has the advantages of compact structure, high degrdd of automation, centralized control and easy operation.

| Technical Parameters | ||||

| Type | SJ50-500 | SJ55-600 | SJ60-700 | |

| Performance | Raw Material | PVC | ||

| Film Thickness(mm) | 0.02-0.08 | |||

| Film Width | 70-400 | 150-500 | 200-600 | |

| Output(kg/h) | 8-40 | 15-50 | 20-60 | |

| Extruder | Screw Diameter(mm) | 50 | 55 | 60 |

| Screw L/D ratio | 28:1 | |||

| Main motor | 11 | 15 | 18.5 | |

| Heating(kw) | 10 | 13.7 | 18.5 | |

| Die Head | Diameter(mm) | 60/80 | 60/120 | 80/140 |

| Heating(kw) | 1.8/2.2 | 2/2.5 | 3/3.5 | |

| Winder | Winding ability(mm) | 400*400 | 400*500 | 400*600 |

| Winding Motor(kg/nm) | 6 | 10 | 10 | |

| Others | Weight(T) | 1.5 | 1.8 | 2.2 |

| Dimensions(M) | 4*1.4*2.5 | 6*2.4*3.5 | 6.2*2.7*3.8 | |

| PS. | The data above may be changed tinily during different time. | |||

Contact us if you need more details on PVC Film Machine. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about PVC Hot Shrink Film、PVC Heat Shrink Film. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : PVC Film Blowing Machine

Premium Related Products

Other Products

Hot Products

High Speed Rotogravure Printing Machine (ASY-600-800-1000)Stretch Cling Film MachinePOF 3-Layer Co-Extrusion Polyolefin Hot Shrink Film ExtruderPE Hot-Shrinkable Film MachinePVC Stretch Cling Film MachineModel Sj500-1700 3-7 Layer Co-Extrusion Film Blowing MachineHydraulic Pressure Rock-Arm Decide Machine (BX-10T)PP Down Blowing 3 Layer Co-Extrusion Film Blowing Machine6 Colors High Speed Flexo Printing Machine (CE)High-Speed (tri-servo) Tri-Sealing Zipper Vertical Bag Making MachineVertical Automatic Slitting MachinePVC Hot Shrink Film Blowing Machine with Rotating TractionAutomatic Multifunction Patch Bag Making MachineGbde Computer Control Double Line Bag Making MachineThree to Five Layers Co-Extrusion Film Blowing MachineMuti Layer Coextruding Agriculture Thick Film Blowing Machine